Talk Something about Impedance PCB

Considerable signal reflection and falsification will occur, thus resulting in design failures if there is no impedance control in the PCB. Normal signals, such as PCI bus, pci-e bus, USB, Ethernet, DDR memory, LVDS signal, etc. also require impedance control. Finally, PCB design will be achieved by impedance control and it can put forward for PCB technology. After talking with PCB manufacturers and combining with the use of EDA software, the trace with impedance control can be made according to the integrity of signal.

Different routing methods can be calculated to obtain the corresponding impedance.

Microstrip line

It is composed of a ribbon conductor and ground plane, with dielectric in the middle. If the dielectric constant of the dielectric, the width of the line, and the distance to the ground plane are controllable, the characteristic impedance of the dielectric is also controllable, and the accuracy is less than + / -5%.

Stripline

A strip is a strip of copper between two conductive surfaces. If the thickness and width of the line, the dielectric constant of the medium, and the distance of the ground plane of the two layers are all controllable, then the characteristic impedance of the line is also controllable, and the precision is within 10%.

Multi-layer structure

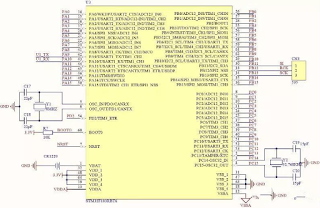

In order to control the impedance of PCB well, the structure of PCB should be understood first.

Generally, the multi-layer pcb is formed by lamination and lamination of the core board and semi-solidified sheet. The core board is a kind of rigid, specific thickness and copper plate, which is the basic material of the printed board. The semi-solidified sheet constitutes the so-called infiltration layer, which ACTS as a bonding core board. Although there is a certain initial thickness, the thickness will change during the pressing process.

The outermost layer of the multilayer pcb is the soldering layer, which is often called "green oil". Of course, it can also be yellow or other colors. The thickness of the solder barrier is generally difficult to determine accurately. The area without copper foil on the surface is slightly thicker than the area with copper foil.

When making a printing board of a certain thickness, on the one hand, it is required to select the parameters of various materials reasonably; on the other hand, the final forming thickness of the semi-cured sheet is smaller than the initial thickness. Here is a typical six-layer laminated structure:

PCB parameters

In different PCB plants, there will be slight differences in PCB parameters. Through communication with technical support of PCB plants, some parameters data of PCB factories can be obtained.

Copper foil: there are three types of copper foil that can is commonly used: 12um, 18um and 35um. The final thickness is about 44um, 50um and 67um after finished products are made.

Core board: the common material are S1141A, the standard FR-4, and two bread copper. The specification can be chosen and confirmed with the PCB manufacturer.

Semi-curing tablet

The specification (original thickness) is 7628 (0.185mm), 2116 (0.105mm), 1080 (0.075mm) and 3313 (0.095mm). The thickness after actual pressing is usually about 10-15um smaller than the original value. The same infiltration layer can use up to three semi-cured tablets, and the thickness of three semi-cured tablets can not be the same, at least one semi-cured tablets, but some manufacturers require at least two.

If the thickness of the semi-cured sheet is insufficient, the copper foil on both sides of the core board can be etched off, and then the semi-cured sheet can be used to adhere on both sides, so that a thicker infiltration layer can be achieved.

Resistance welding layer: the thickness of the resistance welding layer on the copper foil is C2 (38-10um), while the thickness of the resistance welding layer on the surface of no copper foil area is C1 (413-15um) according to the thickness of the surface copper. When the thickness of the surface copper is 45um, C1 (17-18um) is when the thickness of the surface copper is 70um.

Cross section of a wire: we think of the cross section of a wire as a rectangle, but it's actually a trapezoid. Taking the TOP layer as an example, when the thickness of copper foil is 1OZ, the upper base of the trapezoid is 1MIL shorter than the lower base. For example, if the line width is 5MIL, the upper base is about 4MIL and the lower base is about 5MIL. The difference between the upper and lower base sides is related to the thickness of copper.

Dielectric constant: the dielectric constant of semi-solidified sheet is related to thickness.

The dielectric constant of the plate is related to the resin material used, the dielectric constant of FR4 board is 4.2-4.7, and will decrease with the increase of frequency.

Dielectric loss factor: the energy consumed by a dielectric material under an alternating electric field is called dielectric loss. The typical value of S1141A is 0.015.

Minimum wire width and spacing to ensure processing: 4mil/4mil.

This post is so useful and valuable to increase our knowledge. I am happy that you have shared great info with us. Grateful to you for sharing an article like this. Copy Pcb Board

ReplyDeleteThe Company reserves the proper, but has no obligation, to monitor disputes between 온라인 카지노 you and other Service customers. The Company reserves the proper to terminate your Services entry if the Company determines, in its sole discretion, that doing so is prudent. Wagering on the Services is proscribed underneath applicable regulation to Account Holders who are bodily positioned within the Commonwealth of Pennsylvania at the time they're utilizing the Services. Additional geographic restrictions could apply within the Commonwealth of Pennsylvania. If your location cannot be confirmed if you end up} utilizing the Services, your use of the Services might be limited and you will not be allowed to place any wagers. If I need to change from gambling on Facebook to a real web site I just go to Google and type in poker and have it .

ReplyDelete